How can bits become atoms before your eyes?

Courses in Digital Fabrication provide students the tools and skills to design and produce parts that start as files in a computer and end as physical objects you can hold in your hand. At UK's School of Art and Visual Studies, we offer classes that teach both the design software for 2D and 3D modeling and the hands-on use of laser cutting and engraving machines, 3D printers, plasma cutters, CNC routers, and more. These tools increase the range of options for making that both art studio and design students can use.

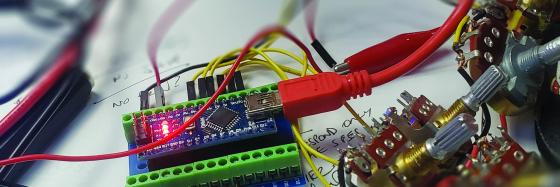

In addition to computer-controlled fabrication tools, students can also learn about programming their own circuits with sensors and actuators to control sound, light and motion. Whether you are interested in sculpture, printmaking, book arts, fibers, graphic design, photography, or ceramics, smart tools can help you take your passions further.

Equipment

- 3D Printers: Form2 SLA printers, Form3 printers, LULZBOT TAZ 5 FDM printers that use elastic to rigid resin and ABS/PA plastic, and the volumes range from 5 to 8 cubic inches. A washing and curing station for post processing.

- 3D Scanning: A 3D Systems RealSense scanner for large volume scanning and a high-precision Matter and Form 3D scanner for smaller volumes.

- Virtual Reality: Oculus Rift headsets running on an Alienware Area-51 Workstation.

- CNC Machining: 24”x36” 3-Axis Laguna IQ CNC router.

- Laser Cutting: A 150-watt BOSS laser with a bed size of 36”x55” as well as a 150-watt Universal PLS675 Laser cutter that allow a variety of materials up to 0.25” thick to be cut.

- Electronics: Interactive workstations for users to take advantage of microcontrollers and microprocessors such as Arduino and Raspberry Pi to program LEDs and control Stepper Motors. All work areas are ventilated with soldering stations and power supplies.

- Vacuum Forming: Formech Vacuum former to shape sheets of plastic using heat.

- Workstations: 15 Dell Precision workstations capable of complex 3D modeling and rendering processes. The PCs are equipped with Rhino3D software and Adobe Creative Suite.

Courses

Classes in the area include introductory, intermediate and project-based Digital Fabrication courses where students learn computer-aided design and manufacturing processes to explore visual art and design issues by producing physical objects. These classes use a mixture of laser cutting, 3D printing, CNC routing, mold-making, vacuum forming and other digital and hybrid processes. Circuits & Bits, a complimentary studio course adds custom software creation and electronics fabrication in an art environment.